Ascatron raising founds & partnering with Pilegrowth Tech

Ascatron signed an investment agreement with the Italian investors Quadrivio (through its venture capital fund TTVenture) and Como Venture, which now has been executed.

Quadrivio and Como Venture together received 16.7% share in Ascatron. Their aim is to continue to actively support Ascatron in order to create a leading industrial group for next generation power semiconductors based on wide bandgap material such as silicon carbide (SiC) and gallium nitride (GaN). The market is growing rapidly with an annual growth rate of 54% to reach US$ 2.0B in 2020.

“This is a first investment from international investors in Ascatron and we are very pleased to having Quadrivio and Como Venture taking lead on our current A-round fund raising”, says Christian Vieider, CEO of Ascatron.

“The money will be used to bring the Buried Grid technology for next generation high performance SiC Power electronic devices to the market”.

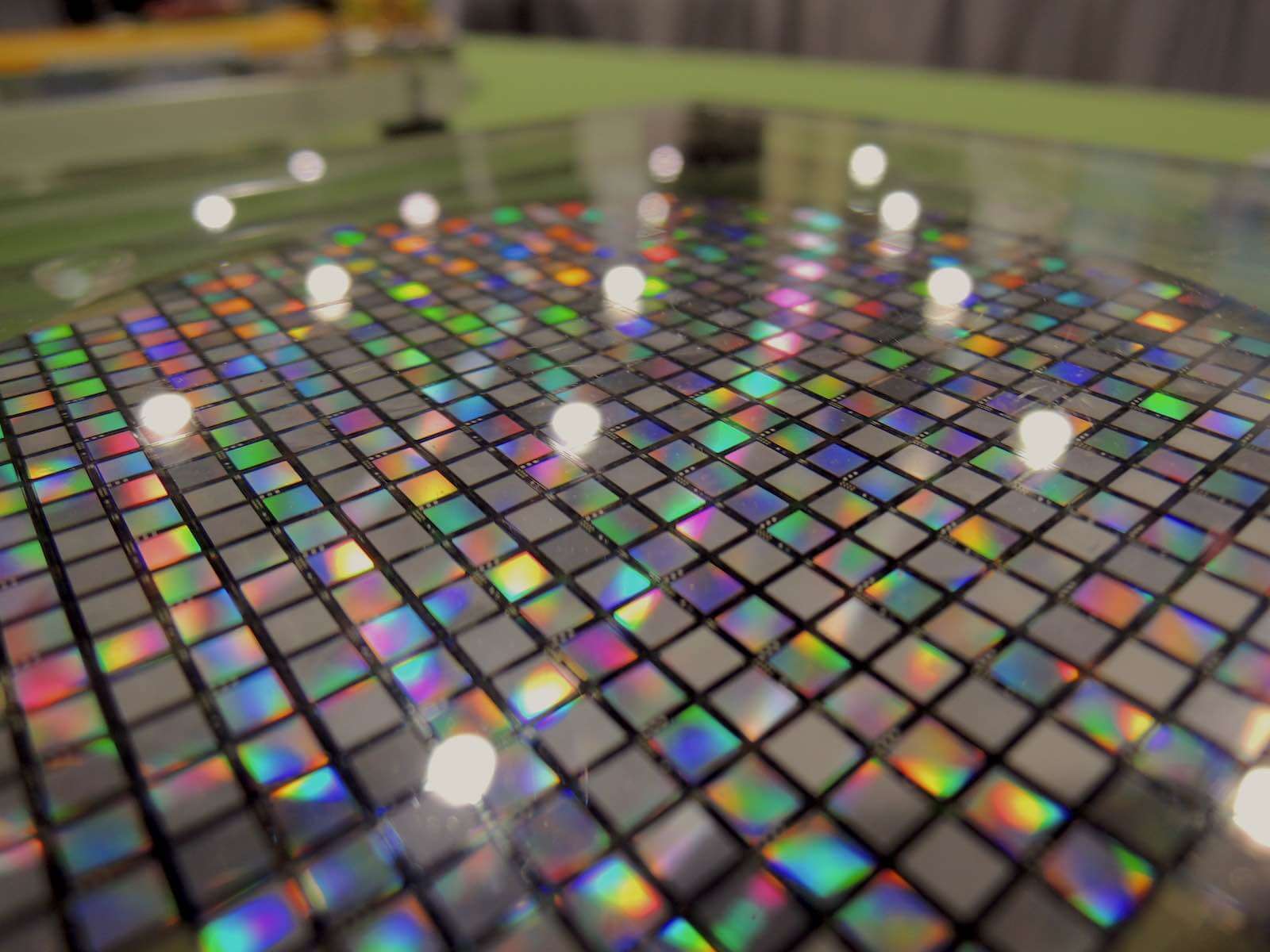

As part of the agreement Ascatron aquired 28.8 % of the shares in PileGrowth Tech, an Italian start-up company based in Milan. Pilegrowth has developed an innovative process for growing different semiconductor materials such as SiC on silicon. The material technology enable Ascatron to also address volume consumer markets with very competitive devices.

“The development of MOSFET transistors based on cubic SiC grown on silicon is an exciting challenge with potential to compete in the 300-1000V market with other semiconductors such as GaN”, according to Adolf Schöner, CTO of Ascatron.

About Ascatron

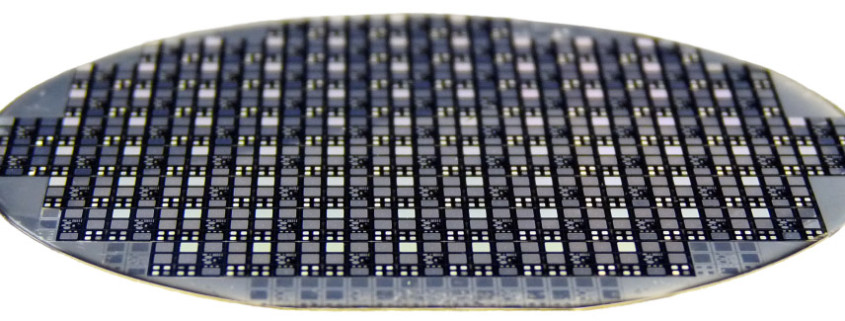

Ascatron develops next generation Silicon Carbide (SiC) power semiconductors radically reducing electrical conversion losses. With the 3DSiC® technology Ascatron provides the active doping structure based on epitaxy, enabling material quality and device performance unattainable through current methods. Ascatron fabricates the epitaxial material in-house and outsources processing of device wafers and chip packaging. Prototype fabrication is done in the Electrum Laboratory in Kista-Stockholm. Target applications range from high temperature for harsh environment to high voltage for wind, traction and data centers mass, as well as volume markets for solar and automotive. Ascatron started the operation in 2011 as a spin-out from the research institute Acreo, and has 10 employees in Sweden.

Leave a Reply

Want to join the discussion?Feel free to contribute!